PAN-DUR Glass – Kompetenzen

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

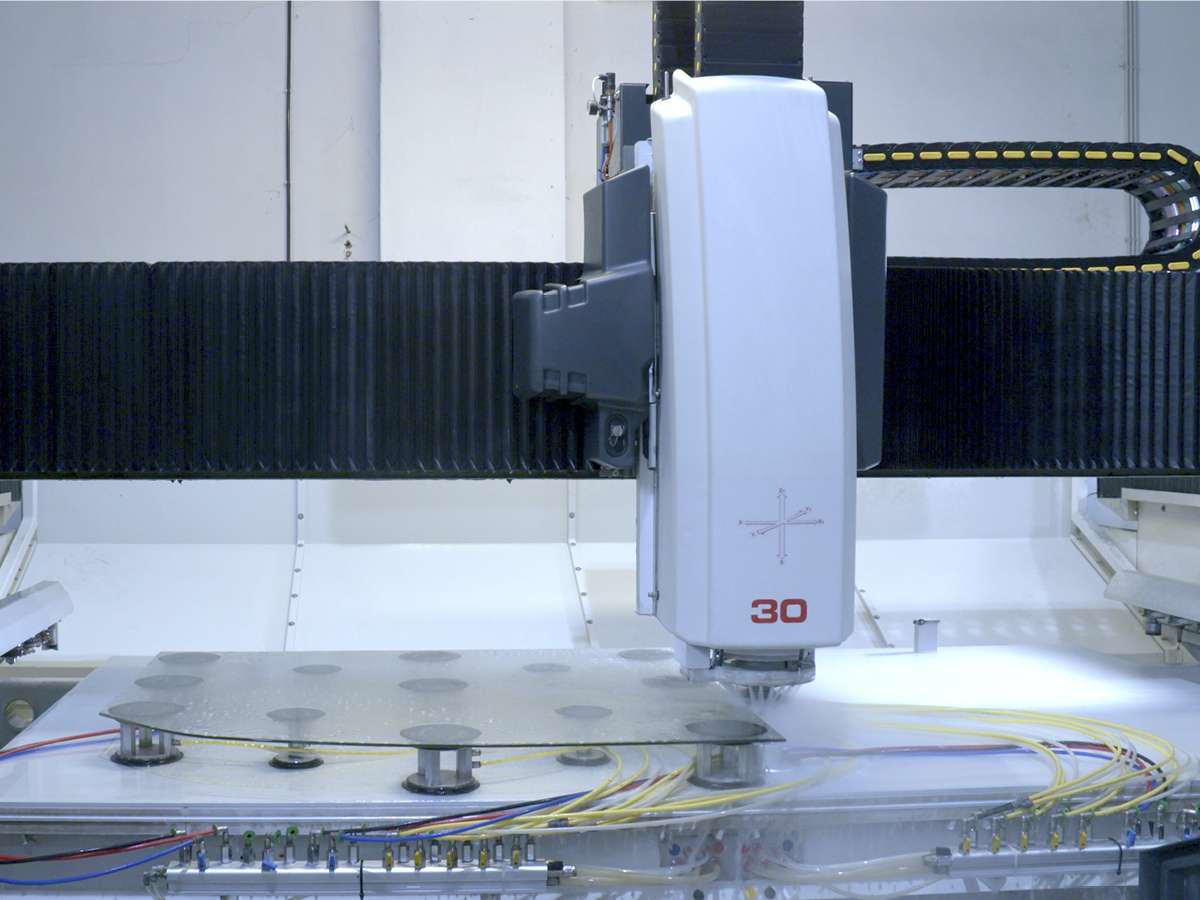

Zuschnitt-, Brechtisch

Vollautomatisches Zuschneiden von Gläsern aller Art und Form aus Band- oder Blattmaßen bis zu 6m x 3.21m.

Verarbeitung von Gläsern mit besonderer Beschichtung (mehrfach entspiegelt, low-e-Beschichtung).

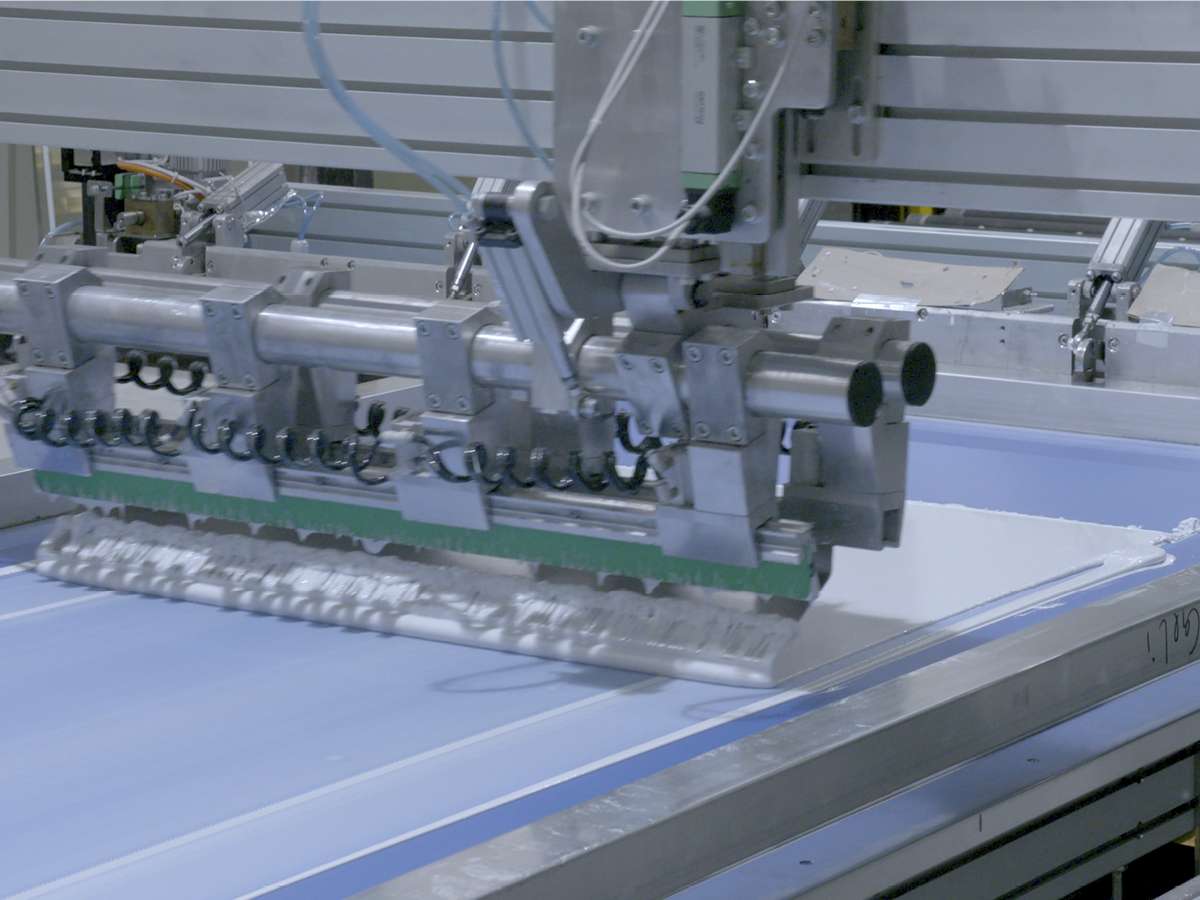

Schleif- und Bohrlinie

Weiterbearbeitung (schleifen, bohren, waschen) in einer Kombinationsanlage. Schleifen der zugeschnittenen Gläser (Übermaß) auf Fertigmaß mit umlaufender C- Kante in matt oder optional auf Hochglanz poliert. Bei Bedarf können die Gläser über eine in die Linie integrierte NC-gesteuerte Bohrmaschine mit einem entsprechenden Bohrbild versehen werden. Am Ende der Linie befindet sich eine Glaswaschmaschine, die auch für sensible low-e-Gläser ausgelegt ist.

Parallel hierzu können die Gläser auch in einem CNC-Bearbeitungszentrum weiterbearbeitet werden. Hier können freie Formen, Ausschnitte uvm. produziert werden.

Durch die intelligente Anordnung der Anlagen können beide Linien über Bypässe einander zuarbeiten.

Siebdruck und Trockenofen

Je nach Kundenanforderung können mittels Siebdruck Dekor- und/oder Funktionsdrucke auf das Glas aufgebracht werden. Unmittelbar nach dem Druckvorgang durchlaufen die frisch bedruckten Gläser einen Trockenofen und werden dem nachgelagerten Vorspannofen zugeführt.

Vorspannofen

Der Vollkonvektionsofen kann mittels Schienensystem und modularer Bauweise drei unabhängige Produktionslinien anfahren.

Linie A = Flachglas

Linie B = zylindrisch gebogene Gläser (Einfachradien)

Linie C = freiform-gebogene Gläser (Mehrfachradien)

Durch das Zusammenspiel von Temperatur, Zeit und Kühlung wird in die verarbeiteten Gläser Einscheibensicherheitsglas gemäß DIN EN 12150 eingearbeitet.

Neben den Produktionsmaschinen und -anlagen verfügt PAN-DUR Glass über einen eigenen Werkzeugbau mit Werkzeugentwicklung sowie eine Montageabteilung zur Konfektionierung und Endmontage einzelner PAN-DUR Systeme.